Description

USE

These canvases can be used in a variety of situations:

1. In the case of a fine cut on a high grain size.

2. In the event of shocks or high loads are to be feared.

FEATURES

Channels

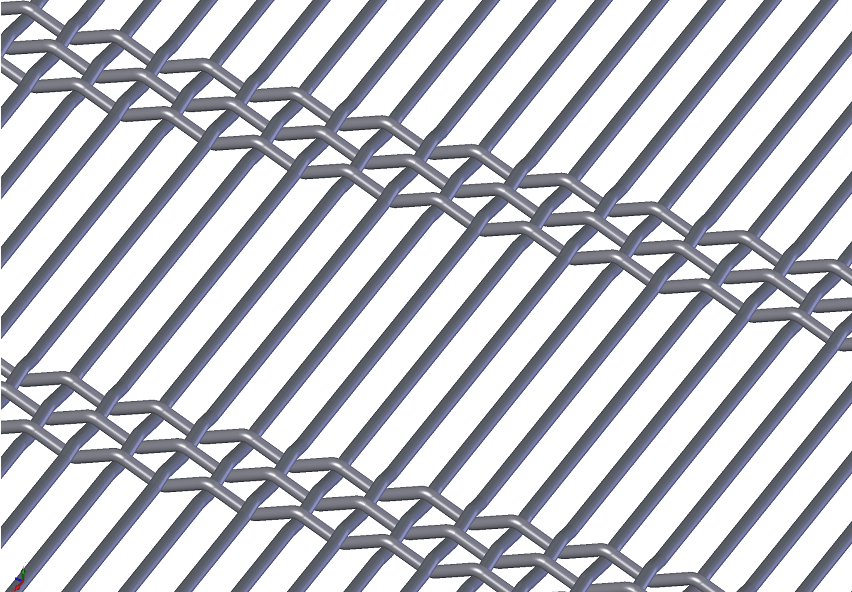

The warp threads, alternating wavy and straight, are independent of each other and form triangular meshes.

As the chains are independent of each other, the shocks produced by the elements to be screened cause differences in vibration that prevent the fine elements from clumping together from one wire to another (clogging).

In addition to this phenomenon, which is identical to ONDAP, the possibility of alternating wavy and straight wires of different diameters also causes a variation in vibration amplitude, accentuated by the fact that one wire is taut and the other free.

Secondly, with a thickness 50% less than conventional screening cloths, the wires do not cross, which explains their high permeability and their high wear resistanceas a result of reduced friction.

Frames

The use of abrasion-resistant rubber or polyurethane instead of steel wire or pre-cut sheet metal wefts was a major improvement at the time.

The wefts, which are necessarily raised in relation to the actual screening surface and therefore subjected to the harshest of screening stresses, are virtually indestructible thanks to the unquestionably superior abrasion resistance of rubber or polyurethane.

The wefts form a one-piece unit, so there’s no possibility of lapping by screening fines, which ensures a much longer service life.

This design also makes it possible to obtain a softer canvas so more vibration-efficientThe wires are no longer constrained by the steel frames.

Reviews

There are no reviews yet.