Description

High Magnetic Field Strength: Offers a range of background magnetic field strengths from 3,500 to 10,000 gauss for effective separation of fine iron and paramagnetic minerals from liquids and slurries.

Applications: Used to remove fine iron and paramagnetic minerals from non-metallic mineral slurries.

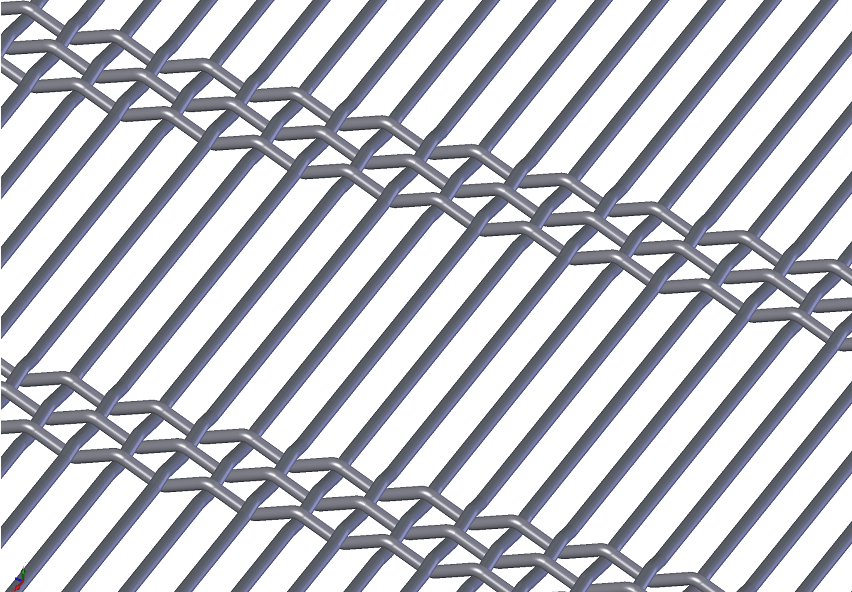

Efficient Separation: Higher separation efficiency than permanent magnetic separators by generating significant background magnetic field strength, and a high-magnetic field gradient on the matrix surface.

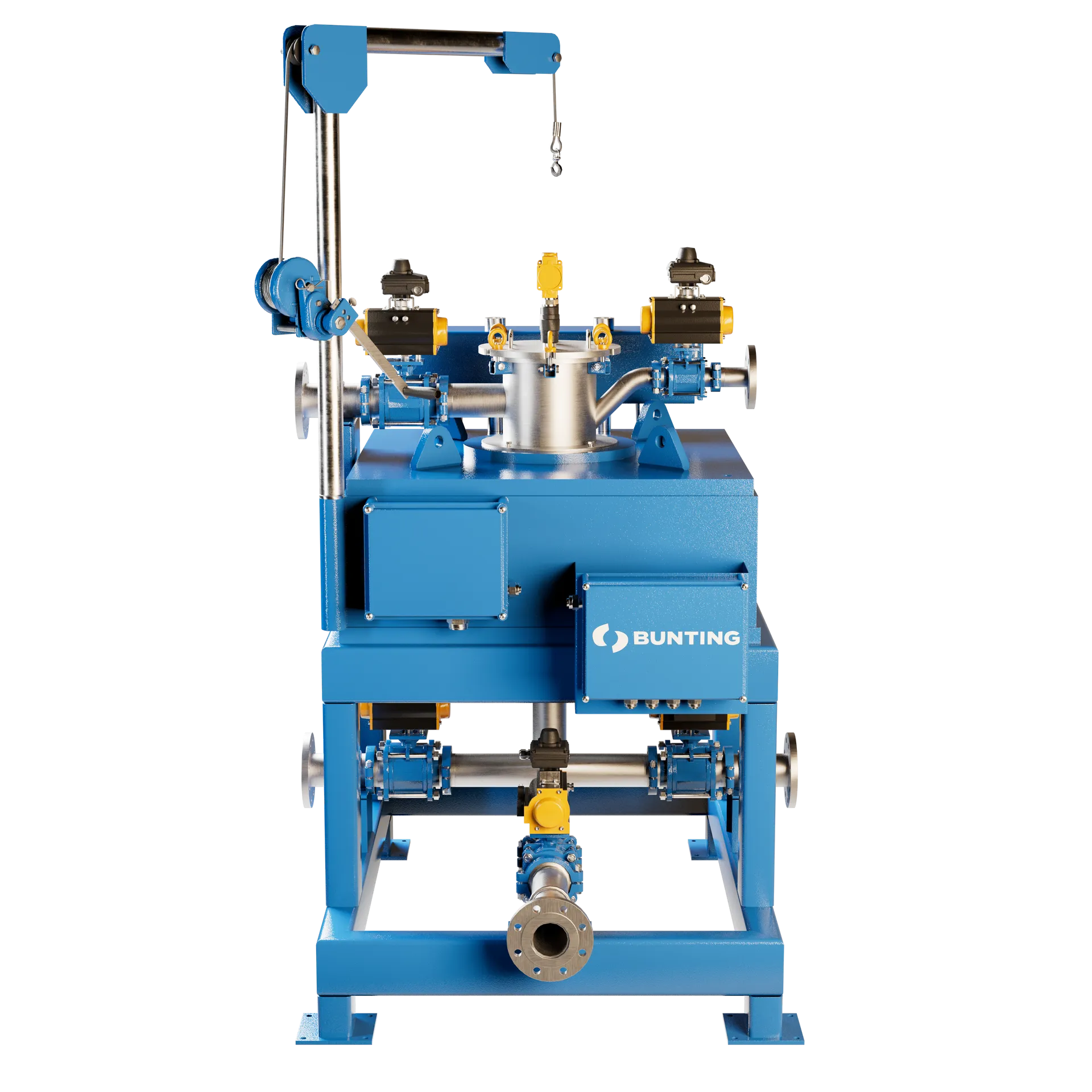

Back Flush Cleaning: Automated back flush cleaning cycle to clean captured contaminants off the matrix. Cycle times can be adjusted via the HMI to suit application needs.

Energy Efficiency: Utilizes highly efficient computer-designed coils paired with an air-over oil heat exchange to maintain optimal operating temperature.

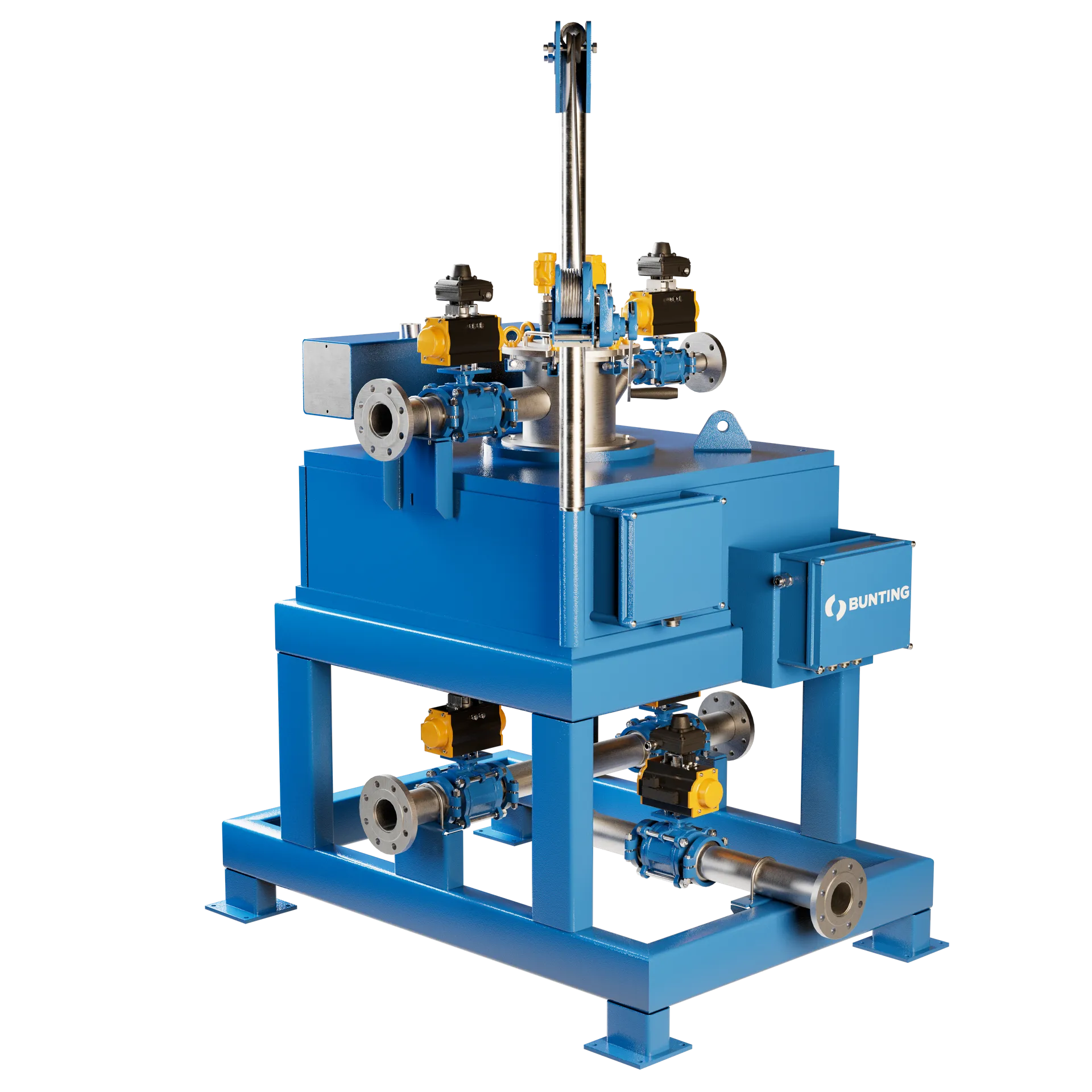

Easy Maintenance: Includes a removable job crane for easy removal of the top pole and matrix assembly for maintenance and cleanings. This minimizes downtime and needs for additional infrastructure.

Controlled Operation: Can be fully automated using a control system with a Siemens S7-1200 PLC and HMI for managing cleaning frequency and parameters.

Valve Configurations: Available in 4-valve to 8-valve configurations to suit different applications.

Testing Facilities: Bunting offers controlled tests on laboratory-sized filters to confirm separation capabilities.

Reviews

There are no reviews yet.